Past the Surface Area: Leveraging Advanced Concrete Scanning Techniques for Unmatched Accuracy and Insight

In the world of building and construction and framework upkeep, the mission for precision and thoroughness is unending. Advanced concrete scanning methods have emerged as essential tools in this search, supplying a glance under the surface to unveil a globe of crucial insights. By taking advantage of cutting-edge innovations, specialists can uncover abnormalities, assess the problem of concrete structures, and make educated decisions that form the course of jobs. The implications of these techniques expand much beyond plain surface-level analyses, promising a depth of precision and understanding that is unrivaled.

Importance of Advanced Concrete Scanning

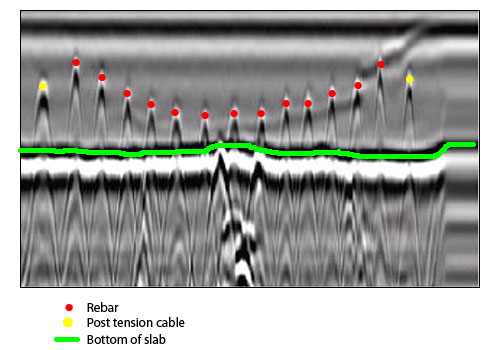

The value of using innovative concrete scanning techniques depends on the exceptional precision they supply for detecting sub-surface anomalies and making sure structural honesty. By utilizing sophisticated technologies such as ground-penetrating radar (GPR), electromagnetic induction, and advanced sonar imaging, building specialists can delve below the surface area of concrete structures with a degree of accuracy that much exceeds conventional inspection methods. Concrete Scanning. These strategies make it possible for the recognition of covert dangers like rebar corrosion, voids, conduits, or post-tension cords that might jeopardize the stability and security of a framework in time

Additionally, advanced concrete scanning offers invaluable understandings into the total condition of a concrete aspect without the requirement for intrusive actions, decreasing the threat of creating damages throughout the analysis process. The capability to pinpoint the exact location and depth of prospective concerns permits targeted repair work and upkeep, eventually prolonging the lifespan of the framework and optimizing its performance. Basically, the relevance of innovative concrete scanning can not be overstated in the world of construction and infrastructure maintenance, where accuracy and reliability are extremely important.

Sorts Of Cutting-Edge Technologies

Anomalies and Problem Discovery

In enhancement to GPR, concrete scanning methods like thermography and impact-echo screening are additionally effective in identifying flaws and abnormalities. By leveraging these sophisticated strategies, specialists can proactively attend to architectural problems, guaranteeing the longevity and safety and security of concrete frameworks.

Assessing Concrete Condition

How can designers accurately evaluate the problem of concrete structures to ensure their long life and safety? Various sophisticated concrete scanning strategies are employed for this purpose. Ground-penetrating radar (GPR) is typically used to analyze the internal framework of concrete, finding gaps, cracks, and various other abnormalities that may jeopardize its strength.

Furthermore, aesthetic evaluation continues to be a basic part of concrete condition analysis. Engineers visually examine the surface for signs of wear and tear, such as spalling, cracking, or discoloration. Combining non-destructive testing approaches with aesthetic examinations enables for an extensive evaluation of concrete problem, enabling engineers to identify potential concerns early and carry out prompt upkeep or repair services. By leveraging these sophisticated methods, designers can make sure the lasting resilience and security of concrete structures.

Enhancing Decision-Making Procedures

In the world of facilities management, optimizing decision-making procedures is essential for guaranteeing their website the effective upkeep and durability of concrete structures. Boosted decision-making processes in concrete management involve utilizing innovative scanning strategies to collect thorough data on the condition of frameworks. By leveraging technologies such as ground-penetrating radar and 3D imaging, stakeholders can make educated decisions concerning support, replacement, or repair work techniques.

These advanced scanning strategies supply indispensable insights right into the inner composition of concrete, recognizing potential problems such as voids, fractures, or rust that may not show up externally. This degree of detailed details enables for aggressive maintenance preparation, decreasing the risk of structural failings and increasing the general life-span of concrete frameworks.

Additionally, by incorporating digital documentation and analysis tools right into the decision-making procedure, stakeholders can track the evolution of concrete conditions over time, allowing predictive maintenance approaches and maximizing resource allotment. Eventually, the assimilation of innovative concrete scanning techniques enhances decision-making processes by supplying unparalleled precision, insight, and efficiency in facilities monitoring.

Verdict

In verdict, advanced concrete scanning methods use exceptional precision and understanding in discovering anomalies, problems, and examining the problem of concrete frameworks. By leveraging cutting-edge technologies, decision-making processes can be enhanced, leading to more informed and effective services for maintaining and fixing concrete framework. These methods play a critical function in making sure the security and long life of concrete frameworks, making them an important device in the area of building and design.

Moreover, advanced concrete scanning provides vital insights right into the overall problem of a concrete component without the need for invasive steps, reducing the danger of creating damages during the evaluation process - Concrete Scanning. An straight from the source additional ingenious technology is 3D X-ray scanning, which supplies comprehensive pictures of the internal structure of concrete, providing useful details without the need for devastating testing. Furthermore, Concrete Cover Meters are made use of to measure the thickness of concrete cover over support bars properly. Improved decision-making processes in concrete administration include making use of innovative scanning methods to gather detailed information on the problem of frameworks.In conclusion, progressed concrete scanning techniques offer unparalleled accuracy and insight in detecting abnormalities, issues, and analyzing the problem of concrete structures